Why Do My Polished Specimens Keep Getting Scratched? 3 Key Reasons & How to Avoid Them

Nothing is more frustrating than when you go to evaluate your sample under a microscope and all you see is scratches across the surface of your specimen. You want your materials lab to run as smoothly as possible and these scratches can slow down your evaluation process, requiring you to start over or redo a sample. The good news is, these scratches can be avoided with the proper precautions, below we take a look at the three main causes for a specimen scratch after polishing and what you can do to avoid them in the future.

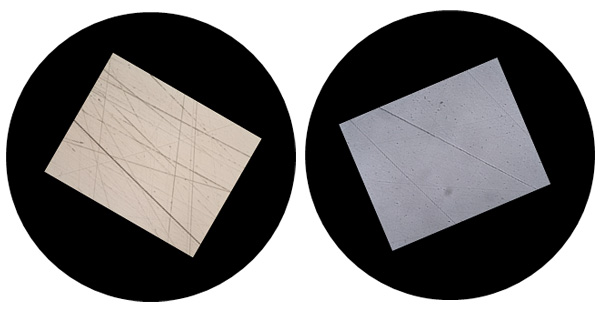

Contamination

Scratches after polishing can result from contamination of a polishing cloth. This can occur if abrasive particles from a previous step are not removed from the specimen or the specimen holder. If a cloth becomes contaminated with larger abrasive particles, it needs to be disposed of. To prevent this sort of contamination, specimens and holders should be thoroughly cleaned prior to each polishing step. Remember that contaminants can be pulled into gaps/voids in the specimen or the mounting material… or any space between them. Proper mounting (hot or cold) goes a long way toward preventing this issue.

Not Enough Abrasive

A polishing cloth deficient in abrasive particles will be unable to polish away previously created scratches. Sometimes this deficiency is due to the cloth being brand new and not “broken in”. It might also be caused by not enough abrasive (diamond, alumina, etc.) in/on the cloth. A fairly common mistake is adding too much extender/lubricant when diamond abrasive is in use. This can cause the specimens to “hydroplane”, keeping them separated from the polishing cloth and diamond particles.

Wrong Polishing Procedure

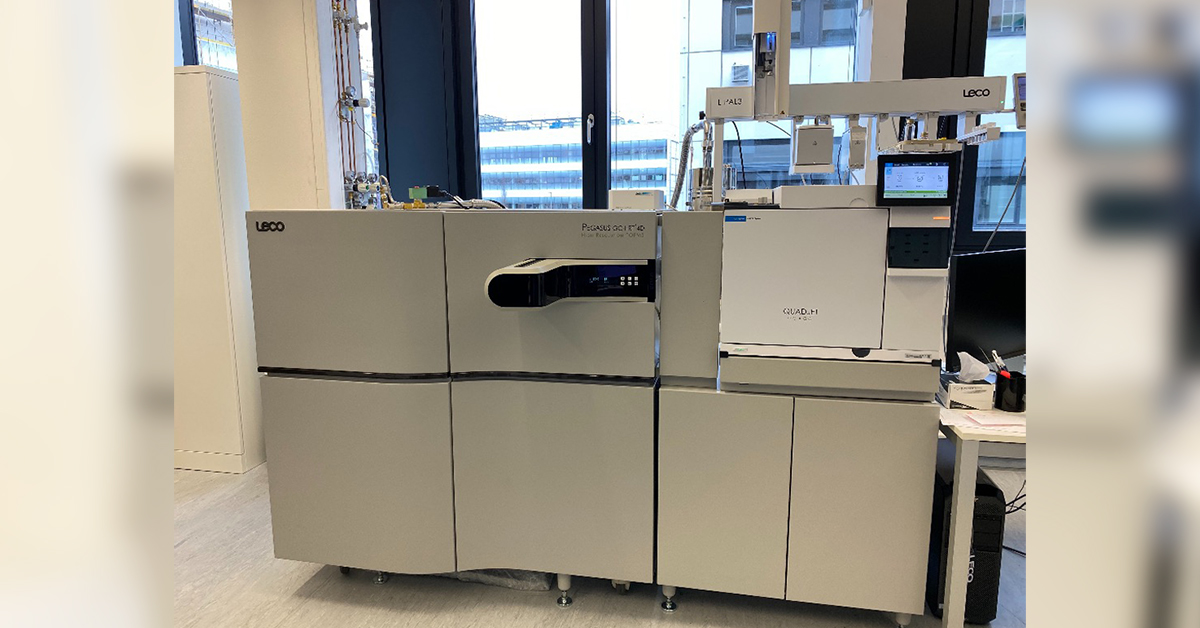

Effective specimen polishing depends on the right mix of a number of variables. Among these are wheel speed, specimen force application, correct cloth/abrasive combination and polishing time. In some instances, scratches are not removed from specimens because the wrong polishing procedure is applied. Be sure to consult LECO’s library of procedures for guidance.