LECO

Empowering Results

LECO

Empowering Results

GDS/Spectroscopy Training Classes

Our GDS training courses provide the customer with in-depth knowledge of the theory of operation, method development, daily operation, proper maintenance, and troubleshooting of their GDS instrument. The training course also allows for networking opportunities and the ability to learn from other users of our GDS900, GDS850, and GDS500 instruments.

Click here to register for classes online, or call (269) 982-5483. Classes are held in St. Joseph, Michigan.

| Upcoming Class Schedule |

| GDS500 October 1-3, 2019 |

| GDS850/QDP Watch for future dates |

| GDS900 October 29-31, 2019 |

Analytical Training Classes

To help customers make the most of our products, LECO’s experienced customer training team provides excellent educational opportunities at our Global Support Center in St. Joseph, Michigan, at our Western Region Support Center in Henderson, Nevada, and at our Ft. Myers, Florida Training Center. Available for a wide variety of LECO analytical instrumentation, our 2½-day training classes incorporate key topics in a combined lecture and “hands-on” format, including:

- Theory of operation

- Daily operation

- Proper maintenance

- Method development

- Troubleshooting

- Advanced features—calibration, drift correction, data export/import,

and database management - Networking with lab professionals

Click here to register for classes online, or call (269) 985-5483.

If you are interested in training for an instrument that does not appear on the schedule, please contact our training coordinator, Mrs. Chris Cook at (269) 985-5483 or email This email address is being protected from spambots. You need JavaScript enabled to view it.

| Upcoming Class Schedule | |

| Date | Location |

| AC600 (NOTE: 2-day Class) December 4-5, 2019 January 29-30, 2020 October 13-14, 2020 |

St. Joseph, MI St. Joseph, MI Ft. Myers, FL |

| CHN/CN/FP 628 October 22-24, 2019 February 11-13, 2020 March 17-19, 2020 July 14-16, 2020 September 15-17, 2020 |

|

| CS/C/S 230 May 5-7, 2020 |

St. Joseph, MI |

| CS/C/S 744 & 844 January 14-16, 2020 February 4-6, 2020 March 3-5, 2020 April 14-16, 2020 June 2-4, 2020 July 21-23, 2020 August 18-20, 2020 September 1-3, 2020 October 27-29, 2020 November 17-19, 2020 |

St. Joseph, MI Ft. Myers, FL Henderson, NV St. Joseph, MI St. Joseph, MI Henderson, NV St. Joseph, MI Ft. Myers, FL St. Joseph, MI Henderson, NV |

| FP/CN 828 January 28-30, 2020 March 17-19, 2020 April 21-23, 2020 June 9-11, 2020 August 4-6, 2020 October 6-8, 2020 |

|

| FP/CN/CNS 928 March 3-5, 2020 April 28-30, 2020 June 2-4, 2020 July 28-30, 2020 |

St. Joseph, MI St. Joseph, MI Henderson, NV St. Joseph, MI |

| ONH/O/N/H/ON/OH/NH 836 & 736 December 10-12, 2019 February 11-13, 2020 March 17-19, 2020 April 28-30, 2020 July 14-16, 2020 September 1-3, 2020 November 10-12, 2020 |

St. Joseph, MI Henderson, NV Ft. Myers, FL Henderson, NV St. Joseph, MI St. Joseph, MI Ft. Myers, FL |

| SC/S/C 832 & 832DR November 5-7, 2019 December 10-12, 2019 January 21-23, 2020 April 21-23, 2020 October 13-15, 2020 |

St. Joseph, MI Ft. Myers, FL St. Joseph, MI Ft. Myers, FL St. Joseph, MI |

| TGA701 November 6-7, 2019 *2-Day Class February 18-20, 2020 |

Ft. Myers, FL St. Joseph, MI |

| TGA801 March 31-April 2, 2020 August 4-6, 2020 October 20-22, 2020 |

St. Joseph, MI Ft. Myers, FL St. Joseph, MI |

| TGM800 (NOTE: 2-day Class) June 24-25, 2020 |

St. Joseph, MI |

| TruMac N/CN/NS/CNS February 25-27, 2020 May 12-14, 2020 August 18-20, 2020 |

St. Joseph, MI St. Joseph, MI Henderson, NV |

Metallography Classes

LECO Corporation brings you the most up-to-date, comprehensive instruction for those working in metallography, metallurgy, quality control, or failure analysis. Our fully equipped Metallography Laboratory and lecture facility provide you with an environment for learning that is second-to-none. We offer services to enhance your learning experience, including course materials, coffee/snack breaks, lunches, one group dinner, and transportation to and from the local airport (as well as between the hotel and the classroom).

Click here to register for classes online, or call (269) 982-2385.

Basic Metallographic Techniques

A 2½-day course in St. Joseph, Michigan covering the complete range of metallographic specimen preparation, micro-/macro-indentation testing, grain size determination, and photomicrography. An overview of optical terms and techniques will also be presented. Each day begins with three hours of lecture, with the rest of each day spent in the laboratory. Students are encouraged to bring samples of materials from their daily work for laboratory analysis. Dates: 2020 dates pending; Course fee is $725 (US)

Principles of Metallurgy and Interpretation of Microstructures in

Ferrous Alloys

A 3-day course in St. Joseph, Michigan covering basic metallurgy principles, binary phase diagrams, TTT diagrams, heat treatment of steel, inclusion classification, and microstructure identification. The class curriculum is all lecture (no lab) and includes daily quizzes. ASM Handbook, Volume 9 (Metallography and Microstructures) is included (a $297 value). Prerequisites: Participants should have a basic working knowledge of metallographic techniques. Date: 2020 date pending; Course fee is $1200 (US)

Chemical Ionization Source

Save time and effort in your laboratory by easily identifying unknowns and having more confidence in your library hits. The chemical ionization (HR-CI) source for the Pegasus GC-HRT+ allows users to dramatically change their high resolution GC/MS information with never before seen mass accuracy and resolution on pseudo-molecular ions. The Pegasus GC-HRT+ is available with both electron ionization (EI) and chemical ionization (CI) sources, providing the option of comparison with classic library spectra (EI), and preservation of the molecular ion (CI). Together, the HR-CI source and the Pegasus GC-HRT+ provide a complete package for high-throughput/high-information content analysis, with resolution up to 50,000 FWHM, mass accuracies less than 1 ppm, and acquisition rates up to 200 spectra/second—all with high-integrity isotopic abundance measurements to facilitate rich information content and high-confidence analyte identification. Click here to learn more.

Click here to view our Technical Brief on Mass Accuracy

LECO’S ACCURATE MASS LIBRARY

Do you want to have the ultimate confidence in your library hit? LECO’s AML allows you to compare accurate mass new sample data against an accurate mass library data set. The AML rank provides a similarity score that uses accurate mass sample data the way it should be used. Click here to learn more.

« back to product menu

MX400 / MX500

Mounting Press Series

Our new fully automatic mounting presses, the MX400/MX500, are your solutions for faster, more sophisticated mounting. The MX400/MX500 boasts a slim, 8-inch wide profile to maximize lab space. A touch-screen display provides easy, user-friendly operation.

Get in touch with us to arrange an individual online demo of the MX400 / MX500 for you!

CONTACT US

- Novel solid steel crossbar closure design is durable, easy to clean, avoids jamming, and allows for quick, one-handed operation

- Intuitive swipe-and-touch user interface makes it easy for you to select heating, cooling, and pressure parameters

- Create fully customizable methods or use a LECO-developed method to fit your exact needs

- Variable modes for mounting delicate samples using all common types of mounting materials

- Low thermal mass for rapid heating and cooling rates for superior productivity

- Reduce mounting bottlenecks and increase throughput with full size dual mount capability in 1.25 inch, 1.50 inch, 30 mm, 40 mm, and 50 mm mold size

- Quickly and easily switch between mold sizes with the MX500

Get a quotation for the MX400 / MX500 today!

CONTACT US

MX400/MX500 Details

- Models

-

MX400

- Mold Sizes: 1.25 in, 1.5 in, 30 mm, 40 mm, or 50 mm

- 115V or 230 V

-

MX500

- Mold Sizes: 1.25 in, 1.5 in, 30 mm, 40 mm, and 50 mm

- 115V or 230 V

-

- Options

-

Mounting supplies

-

Top exhaust panel

-

Mold sleeves

-

Water recirculator

-

- Product literature

MX400

MX500 - Consumables

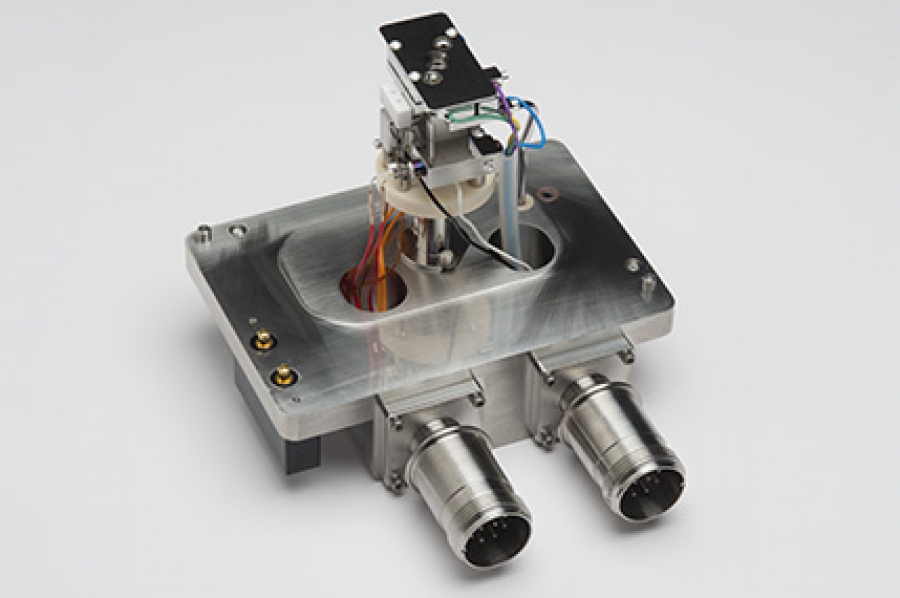

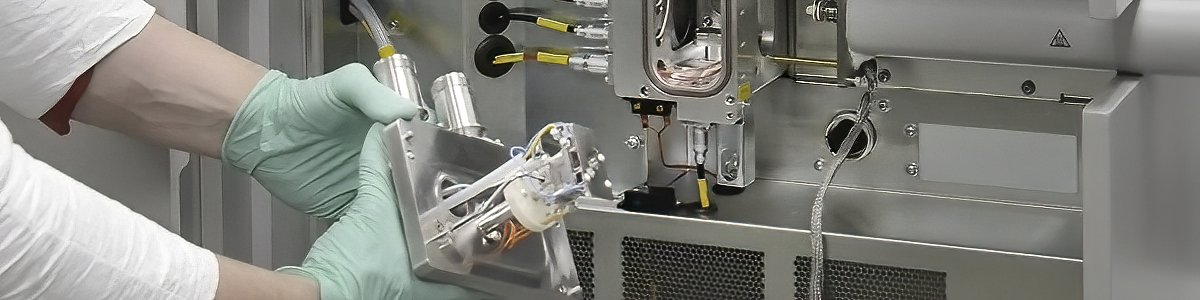

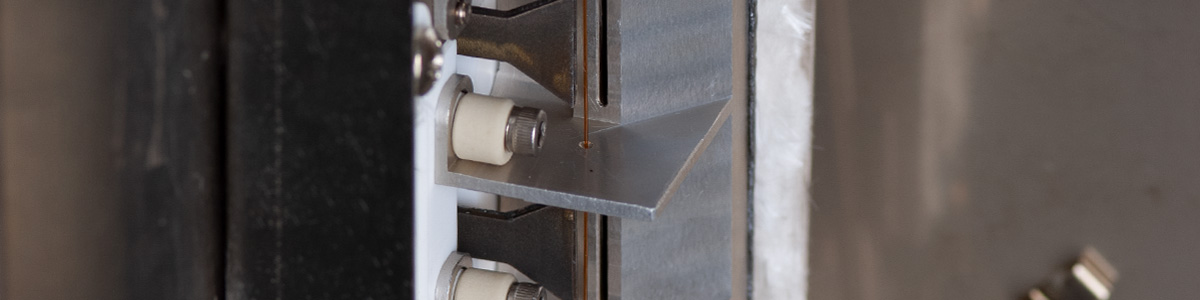

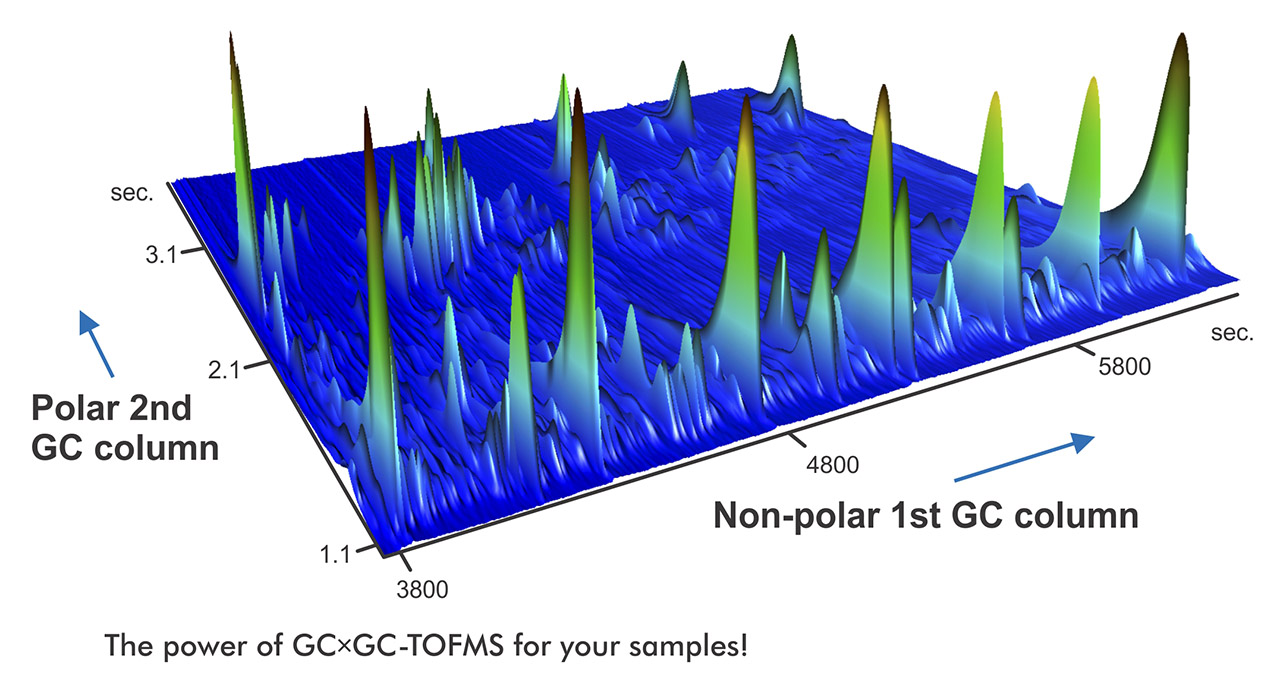

QUADJET™ Thermal Modulator

Thermal modulation delivers the highest performance of any available modulator for GCxGC. Other types of thermal or valve-based modulators do not match up to the ruggedness, reliability, and performance of LECO's GCxGC modulator. With LECO's GCxGC system, modulation is accomplished via a dual-stage, quad-jet thermal modulator positioned between the two columns. LECO's thermal modulator allows for on-column cryo-focusing within the GCxGC system, providing increased peak detectability and increased separation of coeluting compounds.

Thermal Modulation Without the Hassle of Liquid Nitrogen

With LECO's Consumable-Free Modulator you can now choose the compound volatility range you need to modulate. If your application requires you to modulate at extreme high volatility, the traditional LN cooled modulator is recommended. However, if your method requires you to modulate moderately volatile compounds, the consumable-free modulator will save you time and money without sacrificing performance.

« back to product menu

Cold Mounting

Castable Mounts

Our castable mounts are ideal for lower volume laboratories and materials that are sensitive to high temperature and pressures.

We offer polyesters, acrylics, and epoxies for your lab's cold mounting needs:

- Polyesters are an economical choice for labs with low sample volume and less concern about specimen edge retention. They provide an excellent way to make a mount quickly and easily.

- Acrylics will cure faster than most other mounting media. They have excellent abrasion characteristics and fair edge retention. Acrylic is typically used for making multiple mounts where hot-mounting is not practical. A pressure vessel—such as our LECOMAT—used during curing will provide a semi-clear mounting material.

- Epoxies provide a hard, chemical, and abrasion-resistant mount. They generally take longer to set up than other castable materials, but have superior flow and shrinkage properties. Long cure epoxies are used to mount the most difficult samples and can be placed in a vacuum to remove entrapped air and fill voids. Epoxies are available in quick-cure formulations that will cure in less than an hour.

Cold Mounting Details

- Models

- Castolite - Polyester

- Lecoset 7000 - Polyester

- Lecoset 7008 - Acrylic

- Quick and Long Cure Epoxies

- Options

- Ring Molds

- Silicone Rubber Molds

- Mold Cups

- Product literature

- Consumables

FLUX™

GC×GC Flow Modulator

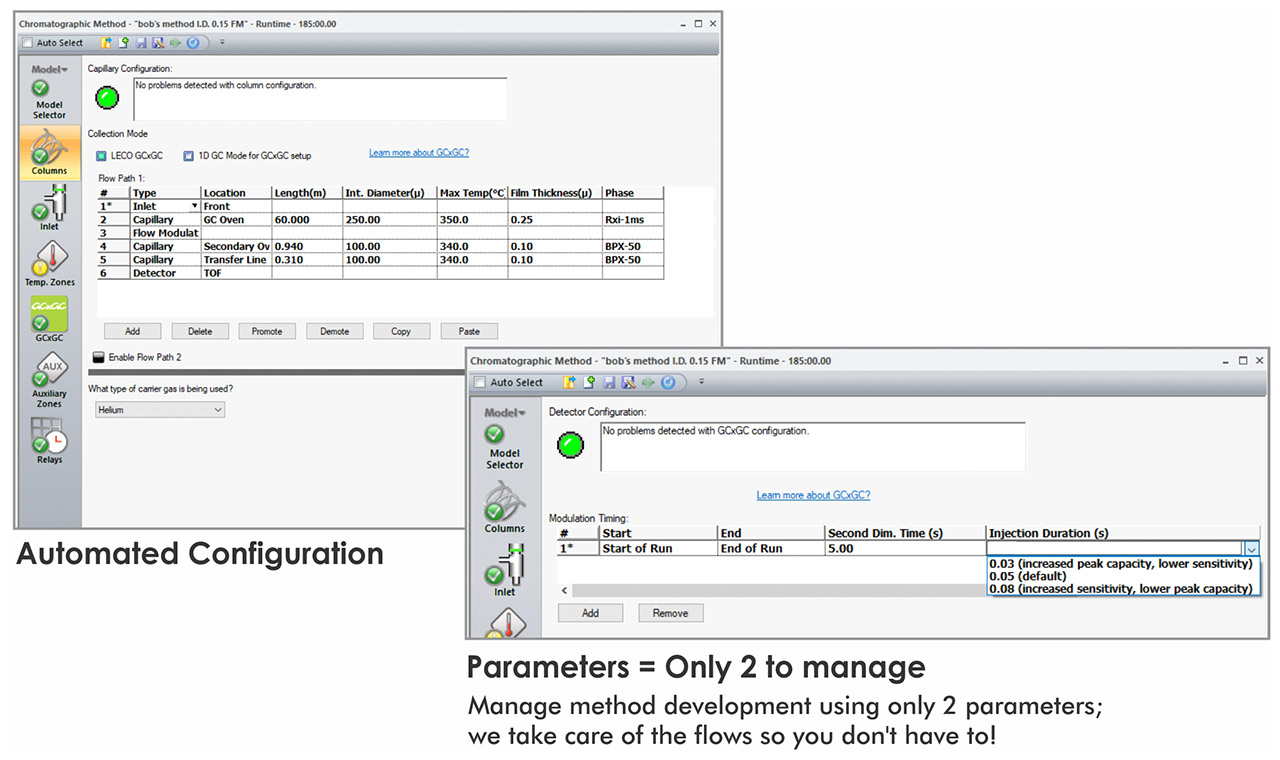

Our innovative FLUX GC×GC flow modulator was designed with one goal in mind—to make GC×GC more routine, accessible, and easier for you. The flow modulator's concept is based on the sound and easily understood principles first articulated by Seeley et al. on diverting flow. This extraordinarily simple design comprising of a cross shape and a sideways T, is not only easy to setup and get started, but its ease-of-use makes it the most cost-effective option for GC×GC analysis.

This flow-based modulator is perfect for those who want to perform robust GC×GC analysis, but who don't need the sensitivity of standard quad jet thermal modulation. Ideal samples should be complex, but relatively concentrated. Appropriate applications include petroleum and fragrance analyses such as the classic weathered crude oil example pictured below, which shows a GC×GC plot generated on our PEGASUS® BT platform using the FLUX flow modulator. .

.

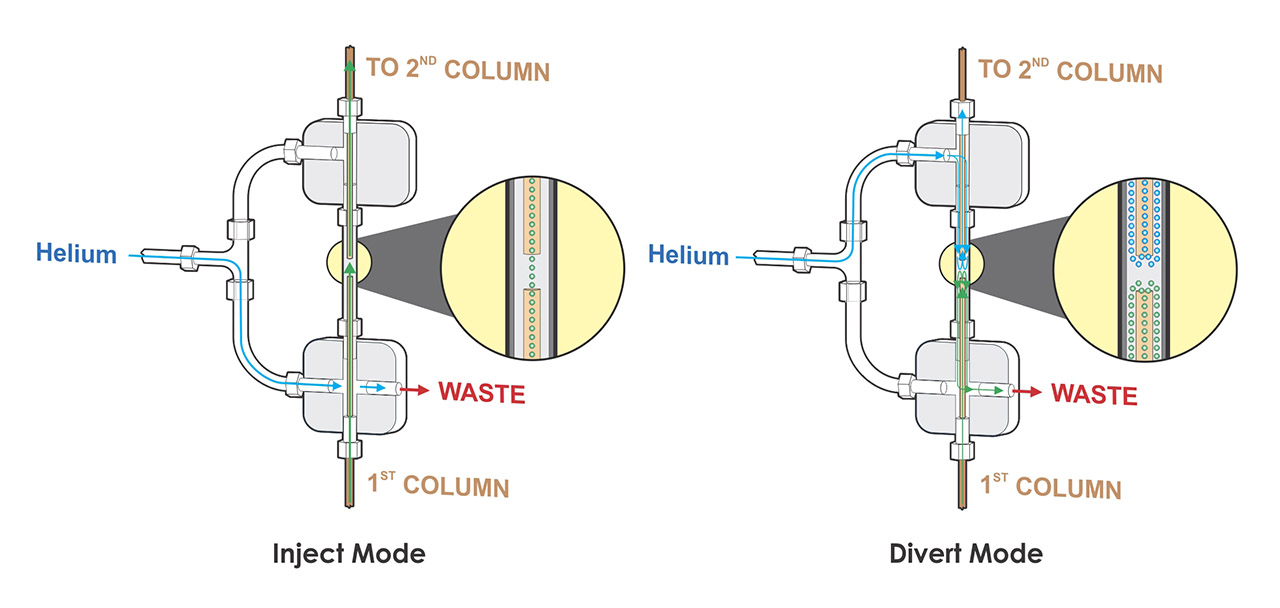

The first and secondary capillary columns are connected together through a simple tube with a fixed gap between the columns. A flow of gas (helium) is then used to inject into the second column or divert to waste. The precise timing and flows are all handled by our integrated software, therefore you just have to click one button to setup and begin performing flow modulation GC×GC on our Pegasus BT platform.  .

.

Furthermore, no complex spreadsheets are needed to understand your method. This simple and robust design does not require cryogens to carry out GC×GC, which saves time and boosts efficiency in your lab.

.

.

Learn more

About Flow Modulation by downloading our white paper "The operation, use, and concepts behind a diverting flow technique."

AF700 Ash Fusion Determinator

Coal and Coke Ash Fusibility Determinator

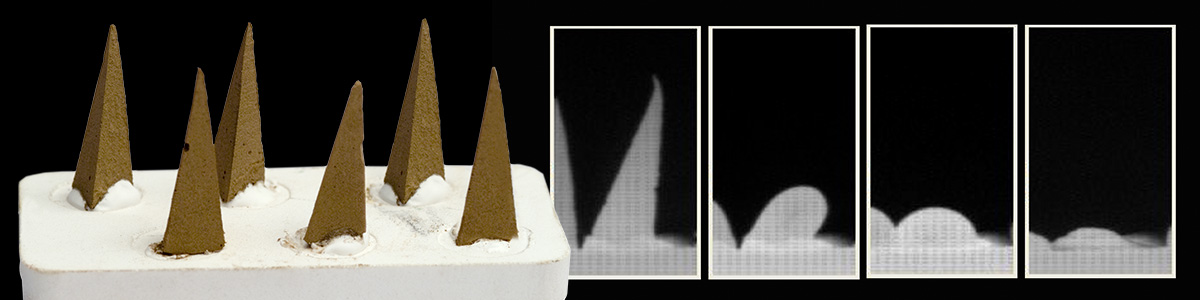

Our AF700 Ash Fusion Determinator increases your laboratory throughput by automatically determining the ash fusibility temperatures (IT, ST, HT, and FT). The state-of-the-art AF700 features improved operational controls, digital archiving ability, integrated safety features, and increased instrument robustness.

- A stable, permanently mounted integrated camera is isolated from the high-temperature area

- An integrated viewing system consistently aligns mirrors with camera and furnace

- A complete image history for all analyzed samples can be digitally archived and retrieved to make objective determinations and confirmations of deformation temperatures

- Door interlocks and an integrated carbon monoxide detector provide increased laboratory safety

- A LED light ring enables low-temperature deformation point measurement

- High-endurance six-element heating furnace provides durability and long-life

Theory of Operation

LECO's AF700 is an ash fusibility determinator that automatically monitors ash cone deformation temperatures in coal ash and coke ash. Prepared ash cones are mounted on a ceramic tray and placed into a high-temperature, rampable furnace. The user selects an analytical method with a predefined furnace atmosphere (oxidizing or reducing) and a ramp rate (°C/minute) for the furnace. Next, a digital camera collects images after the furnace temperature reaches the method-defined starting point. Predefined ash fusibility temperatures (IT, ST, HT, and FT) may be automatically determined using Image Recognition Functions (IRF) within the software. In addition, IRF allows the option of analysis to be automatically terminated after all deformation points have been reached for all samples—increasing throughput and furnace lifetime. A complete image history for all analyzed samples is digitally archived for easy retrieval And review on DVD, CD-RW, or hard drive. Archived images may be used to make subjective determinations of deformation temperatures.

AF700 Details

- Models

-

AF700 Single Furnace System

-

AF700 Dual Furnace System

-

- Product literature

AF700 - Consumables

United States

![]()

LECO Corporation World Headquarters

3000 Lakeview Avenue

St. Joseph, Michigan 49085

Phone: 269-985-5496

Fax: 269-982-8977

Consumables Hotline: 1-800-292-6141

Website: leco.com

General Questions: This email address is being protected from spambots. You need JavaScript enabled to view it.

Pricing/Product Info: This email address is being protected from spambots. You need JavaScript enabled to view it.

Technical Service Group

Eastern Region: 724-935-8336

Central Region: 269-982-5497

Western Region: 702-263-8547

Fax: 269-983-1477

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Spectroscopy Service Group - St. Joseph, MI

GDS: 269-982-5405

Separation Science: 888-LECO911 (888-532-6911)

Applications

Metallographic: 269-982-2293

Analytical: 269-982-2277

Spectrometers: 269-982-2278

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.