LECO

Empowering Results

LECO

Empowering Results

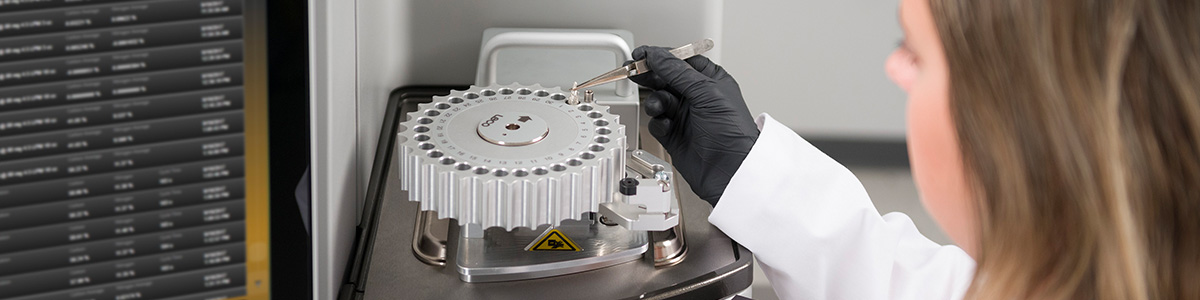

828 Series Macro Combustion

Carbon, Hydrogen, Nitrogen, and Protein Determinator

By incorporating state-of-the-art hardware and an on-board, touch-screen software platform, the 828 Series allows you to easily handle a wide range of sample applications. The the core capabilities and performance of previous generations of LECO macro combustion instruments have been maintained, while key improvements have been made in throughput, uptime, and reliability. All 828 Series models are compatible with the S832 add-on providing independent sulfur determination. Macro sample mass capability paired with cycle times as fast as 2.8 minutes make the 828 an ideal instrument for a diverse applications base, while delivering unparalleled sample analysis throughput.

- Maximize laboratory productivity with unmatched sample throughput

- Rapid cycle time of 2.8 minutes for added productivity on FP/CN models

- Extended reagent lifetimes optimize instrument up-time

- Easy access to common maintenance areas reduces downtime and time required for routine maintenance.

- Rugged 30-sample autoloader with optional expanded capacity for up to 120 samples maximizes lab efficiency.

- Ergonomic, operator-centered design with boom-mounted touch-screen interface

- Expanded furnace efficiency and reliability with a regent-free design

Applications

The 828 series is ideal for the following applications: Feeds, Pet Foods, Grains and Cereals, Milled Products, Fermentation Products, Dairy Whey and Cheese Products, Soils, Sediments, Fertilizers, Plant Tissue, Waste Materials, Resins and Polymers, Coal and Coke, Biomass Materials, and Petroleum Products and Additives.

The 828 Series determines nitrogen/protein, carbon/nitrogen and carbon/hydrogen/nitrogen in a multitude of organic matrices from food/feeds and soils to fuels. The system utilizes a combustion technique with a vertical quartz furnace designed to handle diverse sample matrices with rapid cycle times and extended reagent lifetimes, delivering unsurpassed throughput coupled with superior instrument uptime. To begin an analysis, the sample is weighed into a tin capsule or encapsulated within tin foil and placed into the loader. A fully automated analysis sequence transfers the sample to a sealed purge chamber, where atmospheric gas is removed. The purged sample is transferred automatically into a reticulated ceramic crucible within the furnace. To ensure complete and rapid combustion (oxidation) of the sample, the furnace environment is composed of pure oxygen with a secondary oxygen flow being directed to the sample within a reticulated crucible via a quartz lance. In the FP and CN828 models, the combustion gases are swept from the furnace through a thermoelectric cooler to remove moisture and are collected in a ballast volume. In the CHN828 model, combustion gases are swept from the furnace through an afterburner containing reagent to scrub sulfur compounds from the gas stream prior to collection in the ballast volume. The gases equilibrate and mix within the ballast before a representative aliquot of the gas is extracted and introduced into a flowing stream of inert gas for analysis. Depending upon the analyzer model, the aliquot gas is carried to a non-dispersive infrared (NDIR) cell for the detection of carbon (as carbon dioxide) and a thermal conductivity cell (TC) to detect nitrogen (N2). In the CHN828 model, the ballast gas is also transferred to a H2O NDIR cell for the determination of hydrogen. Unlike NDIR cells, TC cells are chemically non-specific, so a series of reagents and scrubbers are used to ensure quantitative detection of N2 without chemical interference. A heated reduction tube, filled with copper, is used to convert nitrogen oxide species (NOx) to N2 and remove excess oxygen. Carbon dioxide (CO2) is removed by LECOSORB and water vapor (H2O) is removed by Anhydrone.

Careful sequencing of the analysis provides maximum sample throughput by interleaving the sample loading sequence with quantitation of the aliquot gases from the previous sample.

Many diagnostic sensing capabilities are included in the 828 Series analyzer. Multiple Pressure Transducers (PT) have been included to provide the ability to leak check individual segments of the flow path.

828 Series Details

- Models

-

FP828 Nitrogen/Protein

-

FP828P Nitrogen/Protein Performance Package

- CN828 Carbon/Nitrogen

- CHN828 Carbon/Hydrogen/Nitrogen

-

- Options

- S832 add-on provides independent sulfur determination of macro samples

-

Boom-Mounted Touch-Screen Monitor

-

Performance Package

- Featured application

FP828 Nitrogen/Protein in Flour - Product literature

828 Series

CHN828 with S832 Add-On - Consumables

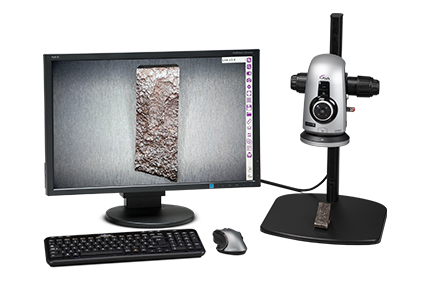

Macro Digital Microscope

Our Macro Digital Imaging System is a self-contained, full HD (1080p) digital microscope and measurement system that conveniently operates without the need for a PC. The system offers powerful image processing and control while delivering full HD live image quality at 60 frames-per-second, which enables it to be used as a solution for your quality control, testing, rework, assembly, inspection, and documentation needs.

- Compact and modular design with no need for a PC

- Applications Suite offers an upgradeable set of inspection and measurement applications including 2D measurement, focus stacking, side-by-side, and overlay image comparison, custom on-screen reticle, and DXF import

- Camera control functions (including auto/manual focus, exposure, gain, brightness, white balance) ensure ultra-sharp, high contrast imaging

- Images can be saved to internal storage or to removable USB flash drive

- Intuitive Graphical User Interface

Macro Digital Details

- Models

-

Macro Digital Microscope

-

- Options

- Product literature

Macro Digital Microscope - Consumables

MSX305R

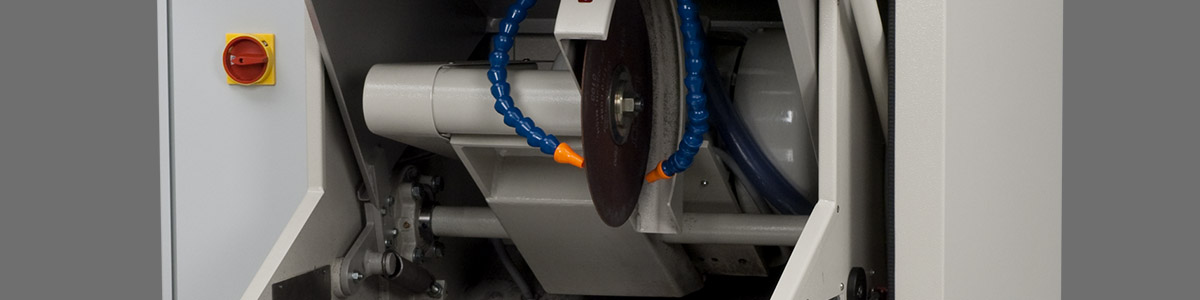

Sectioning Machines

The MSX305R Series is designed for sectioning large samples of many different types of materials. A manually adjustable Y-axis table provides easy sample position and parallel sectioning. Models support up to 14 in (350 mm) blades, and feature a powerful 10.05 HP (7.5 kW) motor and solid-steel construction.

- Production-grade spindle supports up to a 14 in (~350 mm) wheel with 1.25 in (32 mm) arbor

- Welded-steel construction for the production environment

- Optional catch basket for capturing small, sectioned samples

- 15.75 in (400 mm) x 15.75 in (400 mm) T-slotted table with large sectioning compartment for versatile sample fixturing

- 30 gallon (115 L) built-in coolant tank with coolant fluid level gauge

- Sealed electronic enclosure and removable side ports

- Convenient, easy-to-operate control panel

- Z-axis locking feature

- Handwheel-driven X- and Y-table for longitudinal section and sample position

MSX305R Details

- Models

MSX305R1 Series- Manual with Y-Table

- 460V or 380-400V

- Manual Y-table and X-axis and radial feed configurations and Y-axis Table

- 460V, or 380-400V

- Manual with Y-Table

- Options

- Catch Basket

- Laser Pointer

- Filter Fleece Blanket

- Product literature

MSX305R - Consumables

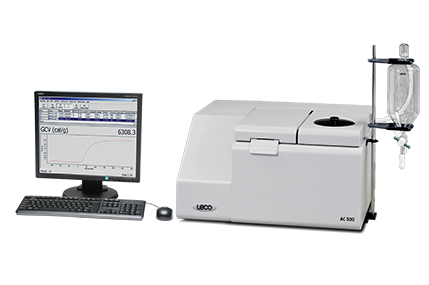

AC500 Isoperibol Calorimeter

Gross Calorific Content

The AC500 determines calorific value, a key indicator of quality and value in solid and liquid fuels, through measurement of the heat released after combustion of a sample. This stand-alone benchtop unit uses a fully-integrated circulation system for a compact footprint—no additional heaters or coolers required. An integral water-measuring station simplifies sample preparation, and the operating system uses an electronic thermometer accurate to 0.0001°C to measure temperature every six seconds. Two-channel correction is possible through constant temperature monitoring in both the outer jacket and the calorimeter proper.

- High precision across a wide range of sample sizes and ambient conditions

- Fuse wire or string-ignition combustion vessel

- Several analysis modes available: Regnault-Pfaundler, Precision, and Predictive

- An optional string-ignition combustion vessel provides a seamless analysis without wire connections.

AC500 Series Details

- Models

-

AC500 with no Vessel

-

AC500 with Wire Igniter Vessel

-

AC500 with String Igniter Vessel

-

- Options

-

Wire Igniter Vessel

-

String Igniter Vessel

-

- Product literature

AC500 - Consumables

AC600 Semi-Automatic Isoperibol Calorimeter

Gross Calorific Content

Ideal for the measurement of calorific content in solid and liquid fuels, LECO’s AC600 semi-automatic isoperibol calorimeter sets the standard for future calorimetry instruments. Its semi-automated operation, combined with the use of thermodynamic TruSpeed®, obtains a rapid analysis of calorific content and increased instrument throughput without sacrificing accuracy or instrument precision. A new, ergonomically-designed, lightweight combustion vessel assures ease of operation while greatly reducing operator strain.

Features

- Enhanced automation for added productivity

- Analysis in as little as 5-minute analysis without compromising accuracy or precision

- Ergonomically-designed vessel promotes easy vessel handling, while enhancing the heat transfer rate

- Integrated vessel charging station and depressurization ports equipped with quick-release handles speed vessel charging and depressurization process.

- Intuitive software provides virtually unlimited storage space, simplified data handling, and compatibility with various Laboratory Information Management Systems (LIMS)

Theory of Operation

The LECO AC600 semi-automatic calorimeter was developed to measure the calorific content of various organic materials such as coal, coke, and fuel oil.

The calorific value of a sample is determined by precisely measuring the heat released after combustion of the sample in a controlled environment. The heat released is proportional to the calorific value of the substance.

The sample is placed into a combustion vessel, which is pressurized with oxygen. The combustion vessel is automatically lowered into a water bath within the instrument known as a bucket. The bucket is sealed using an inflatable bladder. The cavity surrounding the bucket is known as the jacket and is also filled with water. The water temperature in the jacket is closely controlled at a precise set temperature (isoperibol calorimeter system). The sample is ignited and the temperature of the bucket and jacket water is measured by an electrical thermometer with a resolution of 0.0001 of a degree. A measurement of the water temperature inside the bucket and jacket is collected every second. The results can be corrected within the software for any spiking, nitrogen, sulfur, moisture, and ash content if necessary. Two options for analyzing data are available. A simple temperature difference may be chosen by the user (Delta T mode), in which calorific values are determined by a simple maximum temperature rise of the bucket. The user may also choose to use a thermodynamic model (TruSpeed mode) that has been developed by LECO to model heat exchange within the AC600 system. The TruSpeed mode takes into account heat capacities of the system's components along with corrections for energy transfer within the system. The TruSpeed mode enables the AC600 to attain rapid 5 minute analysis times without compromising the accuracy or precision of the calorific result.

AC600 Series Details

- Models

-

AC600 with standard vessel

-

AC600 with halogen-resistant vessel

-

Dual AC600 with standard vessels

- Dual AC600 with halogen-resistant vessels

-

- Options

-

Standard vessel for wire or thread ignition

-

Halogen-resistant vessel for wire or thread ignition

- Recirculating water chiller

-

- Featured application

Gross Calorific Value Coal - Product literature

AC600 - Consumables

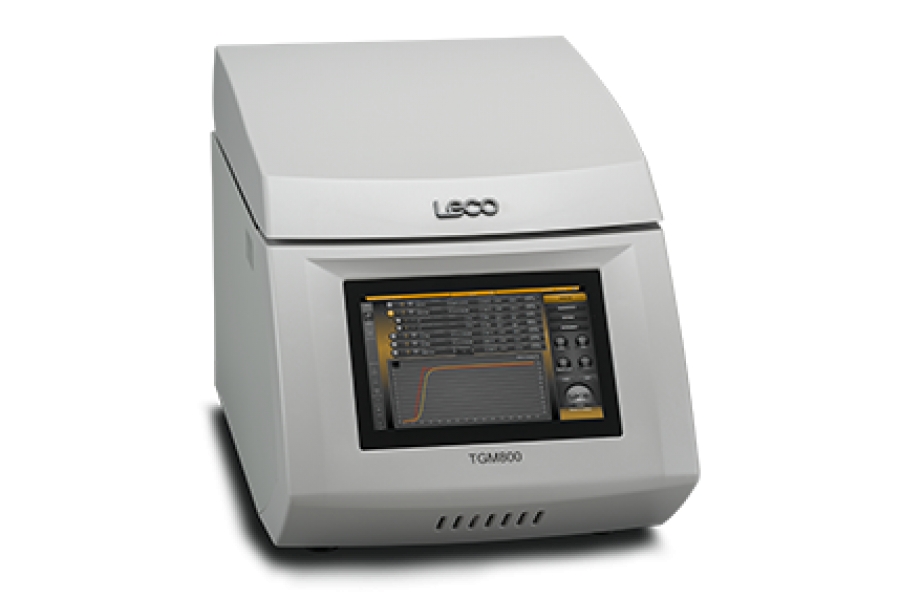

TGM800

Thermogravimetric Moisture Determinator

The TGM800 provides a high precision, automated solution for moisture determination by replacing the slow, laborous, traditional loss-on-drying technique with an automated primary method. A number of time-saving features have been incorporated into this design, such as the ability to automatically measure up to 16 samples at a time with optional drying time end point recognition, and intuitive touch-screen software with flexible method settings. The TGM800 is applicable to a wide variety of sample matrices including food, feeds, milled products, and agricultural materials, making it a versatile solution for many laboratories.

Features

- Automated loss-on-drying moisture analysis of up to:

- 16 samples using 1.5 inch diameter aluminum foil crucibles

- 10 samples using 2.4 inch diameter aluminum foil crucibles

- Maximized throughput with rapid ramping of the oven temperature and fast cooling post analysis

- Optimized drying time with automatic end point recognition based upon sample mass constancy

- Limited sample interaction requirements for reduced operator handling time

- Integrated 10.1 inch (diagonal) color LCD touch-screen with Cornerstone® software reduces instrument footprint, and promotes an ergonomic and efficient workflow

Theory of Operation

The TGM800 is a thermogravimetric analyzer designed to directly determine moisture content of materials using a loss-on-drying technique. Mass loss of the sample is measured as a function of the oven temperature while controlling the atmosphere and ventilation rate. The instrument consists of a computer, an integrated four place balance, and a multiple sample oven that allows up to 16 samples to be analyzed simultaneously.

After an analysis method has been selected, empty aluminum foil crucibles are loaded into the oven carousel. The analysis method controls the carousel, oven, atmosphere ventilation, and balance operation. On completion of crucible tare, each crucible is presented to the operator for sample loading. The initial sample mass is measured and stored automatically. Once all the samples have been loaded, the analysis starts with the oven temperature ramping to the set point, the beginning of ventilation, and the sequential collection of the individual sample masses. Crucibles are automatically indexed to the position above and lowered onto the balance pedestal where the sample mass is recorded. The mass loss of each sample is monitored, and the oven temperature and atmosphere ventilation rate is controlled according to the selected analysis method. Method analysis length can be programed to a fixed time or be dependent on the sample mass constancy. The moisture result is calculated as a percent mass loss for each sample and reported at the end of the analysis.

The instrument contains an intuitive touchscreen interface that enables complete access to analysis control, method settings, diagnostics, sample reporting, and more in a highly organized and immersive environment. Analysis methods can be tailored to satisfy most moisture applications with editable oven temperature, temperature ramp rate, atmosphere, and ventilation rate. The software also provides on-screen plotting of sample mass loss and temperature, as well as storing and managing all of the data and quantitative calculations.

The TGM800 maximizes lab efficiency, productivity, and analytical performance with a sample batch capacity up to 16 samples with sequential sample mass measurements occurring throughout the analysis process.

TGM800 Details

- Models

-

TGM800 Thermogravimetric Moisture

-

- Options

- Featured application

Determination of Moisture in Flour - Product literature

TGM800 - Consumables

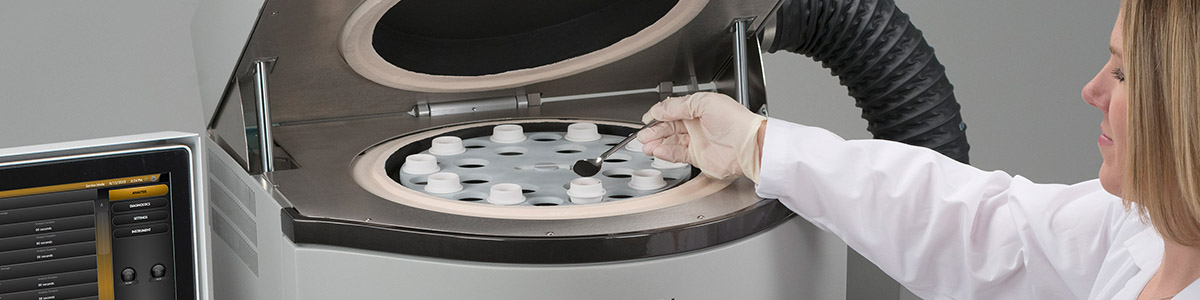

TGA801 Thermogravimetric Analyser

Moisture, Ash, Volatile Content, and Loss-on-Ignition

The TGA801 maintains the core capabilities and reliability of previous generations of LECO macro TGA instruments, while providing key improvements in performance and robustness. State-of-the-art hardware combined with a touch-screen software platform and rugged design provides accurate, high-precision thermogravimetric constituent analysis—moisture, ash, volatile content, and LOI in various organic, inorganic, and synthetic materials. Complying with ASTM standardized methods, the TGA801 is applicable to many industries and applications including coal, cement, catalyst, foods, and feeds.

Macro thermogravimetric analysis (nominal 1 g) replaces the often slow, labor-intensive, traditional manual gravimetric techniques that require multiple sample weighing and transfer steps involving ovens, muffle furnaces, and desiccator equipment. Flexible method settings, automation, and hardware capabilities deliver an automated analysis process while requiring only the manual measurement of the initial sample mass, for maximum productivity in your lab.

Cornerstone Mobile remote software keeps the user updated from their smartphone, tablet, or PC on the instrument's analysis batch progress, performance, and status while away from the instrument.

- Automated analysis of up to 19 samples for increased throughput.

- Automatic end point recognition based upon sample mass constancy

- Stable and precise mass measurements throughout the analysis cycle using an integrated, thermally isolated 0.0001 g low drift balance

- Precise furnace temperature ramping and set point control provides excellent temperature accuracy with low temperature overshoot

- Rotating automation sequence provides uniform exposure of all samples to the furnace conditions

- Automated control of furnace atmosphere and gas flows (air, nitrogen, or oxygen)

- Flexible method settings enable configuration of system to emulate classic gravimetric test method requirements

Applications

The TGA801 is ideal for the following applications: Coal and Coke, Combustion Residues, Biomass Materials, Catalyst Materials, Soil and Ore Materials, Ceramics, Gypsum and Building Materials, Hydrated Lime and Cement, Flour and Milled Products, Feed Materials, and Resins and Polymers

The TGA801 Thermogravimetric Analyzer determines weight loss, including moisture, ash, volatile content, and Loss-on-Ignition (LOI), in various organic, inorganic, and synthetic materials. Weight change is measured as a function of temperature as samples are exposed to a temperature program in an atmosphere-controlled environment. The multi-sample furnace design allows for simultaneous analysis of up to 19 samples.

Analysis begins when samples have been logged in and empty crucibles have been loaded into the sample carousel. After empty crucible weights have been automatically recorded, the user is prompted to load samples. Once loaded, sample weights are recorded and the method-specified furnace-temperature program begins. One of three analytical gases (air, N2, or O2) are used to control the atmosphere inside the furnace during the course of an analysis. Temperature, temperature ramp rate, atmosphere, and duration (fixed time or mass constancy) are selectable for each method step. Moisture, volatile, and ash steps are most commonly utilized and are available as preset method steps.

The mass change of each sample is sequentially monitored throughout an analysis. Crucibles are automatically indexed to the position above (and lowered onto) the balance pedestal where sample weights are recorded. Percent mass change is typically reported at the end of each step; although alternative and additional calculations can be specified by the user in the method.

An external PC with LECO Cornerstone® brand software manages all of the quantitative calculations and saves all of the data.

TGA801 Details

- Models

-

TGA801 Thermogravimetric Analyzer

-

TGA801 Dual Furnace Package

-

- Options

-

Desktop Touch-Screen Monitor (M)

-

- Featured application

Moisture, Volatile Matter, Ash, and Fixed Carbon in Coal - Product literature

TGA801

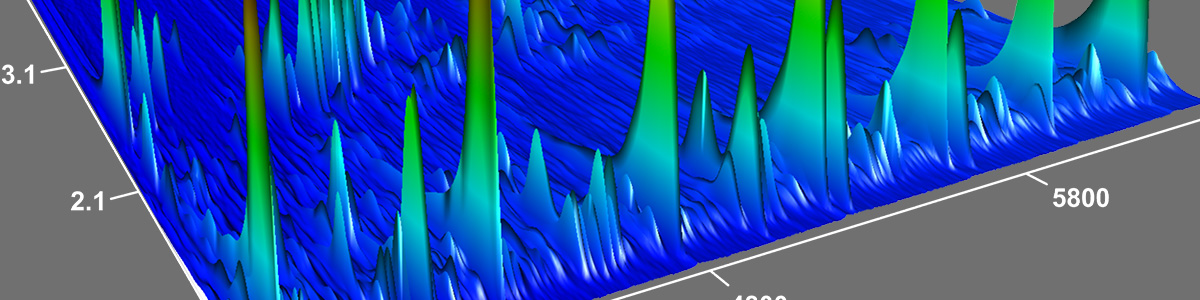

ChromaTOF® Brand Software

Developed exclusively by LECO, ChromaTOF is uniquely designed to meet the needs of today’s laboratory professionals by processing and analyzing the large amounts of data that are acquired with our time-of-flight instruments. ChromaTOF offers seamless control of both the instrument and its accessories, as well as an intuitive interface with highly integrated data processing. ChromaTOF is the first mass spectrometry data system to fully accommodate multidimensional chromatographic data (GC×GC).

What Makes ChromaTOF Unique?

- Data processing is automatically saved within the file system—no extra steps are needed and you can always come back to where you left off

- Data file system stores and manages meta- and instrument data for you

- All standard features are contained within one software package; control for some compatible options is built–in and can be activated when needed

- Easy-to-use, yet powerful, efficient, and robust

- Frequently updated for improved maintenance and additional feature development

ChromaTOF Version 5.0 encapsulates the industry’s most advanced qualitative and quantitative capabilities in one user-friendly data-handling system. Supports both Pegasus BT and Pegasus GC-HRT+ instrument platforms.

Features

- Automatic tuning and associated report generation

- Absolute concentration of analytes based on calibration curve

- Relative quantitation based on a reference’s or analyte’s curve

- Quantitation from a single channel detector (Flame Ionization Detection FID)

- Importable ready-to-use workspace templates for access to preferred user interfaces and reduced set-up times

- Deconvoluted spectra are easily searched against the latest NIST, Wiley, or user-created library for identification

- Semi-Quantitative Analysis for the reporting of non-calibrated compounds

- Integrated control of a variety of sample handling options from LECO and Agilent; contact closure for other vendors

- Automatically export data to CSV, ANDI MS, NETCDF, or LECO file formats

- Compatibility with LECO's liquid nitrogen or consumable-free GCxGC thermal modulator

- GC×GC Classification development tools

- Integrated control of Agilent 7890GC

- Search for unknown unknowns with ChemSpider

- Helpful tools to:

- Calculate monoisotopic mass from formulae

- Generate formulae from measured mass

- Calculate mass resolution needed to separate 2 masses

Features Exclusively for Pegasus GC-HRT+

- Automated unknown identification with High Resolution Deconvolution algorithm

- Automatic fragment formula generation and corresponding mass accuracies from NIST generated library matches

- Create and use Accurate Mass Spectral Libraries. New LECO Accurate Mass Library, built for the GC-HRT+ gives you complete confidence that a hit is strong identification. Calculate a similarity score (AML Rank) based on accurate masses

- User-scalable mass defect plots; e.g. Kendrick mass defect scale

- Optional Spectral Analysis Tool add-on allows you to use Van Krevelen and Carbon Number versus RDBE (ring double bond equivalents) plots, and many other advantages

Pegasus BT Features

- Automated unknown identification with NonTarget Deconvolution algorithm

- Full profile mass spectra at are acquired at 35 kHz with better than nominal resolution

| Pegasus Instrument Model | Latest ChromaTOF Version |

Major Features |

|

GC-HRT |

5.10 | Addition of the L-PAL3 and Spectral Analysis Tools |

|

GC-HRT |

5.10 | Addition of the L-PAL3 and Spectral Analysis Tools |

| GCxGC FID 4D, HT (incl “C”) TruTOF |

4.72 | Fixes |

| BT BT 4D |

5.32.09 |

Added nominal mass data export |

|

GC-HRT+ |

5.32.12 |

Identification Grading System and |

Used by industry leaders for over 15 years, ChromaTOF-GC supports GC×GC deconvolution, visualization, and reporting.

- True Signal Deconvolution, Automated Peak Find, and Extended Range Calibration algorithms

- Enhanced graphics for GCxGC users, including the option of displaying peak labels and peak markers on contour and surface plots

- Importable ready-to-use workspace templates for access to preferred user interfaces and reduced set-up times

- Semi-Quantitative Analysis for the reporting of non-calibrated compounds

- Automatic tuning within user-defined quality control methods

- Integrated control of a variety of sample handling options from Gerstel, LEAP, Shimadzu, and Agilent

- Fully-integrated optional environmental report designer

- Customizable user interface

- Automatically export data to PDF, CSV, ANDI MS, NETCDF, or Raw file formats

- Compatibility with LECO's consumable-free GC×GC thermal modulator

- Classification development tools

- Capacity for files up to 4 GB and compatibility with Windows operating systems

- The LECO/Fiehn Metabolomics Library features over 1,100 spectra of 700 unique metabolomics for metabolite identification in your most complex samples. Fully integrated within ChromaTOF, the library works seamlessly with the software's Library Search function to automatically identify potential analyte matches without the need for importing or exporting data.

Simply GC×GC®

The easier way to make GC×GC part of your every-day analysis

Simply GC×GC from LECO is a free tool designed to walk you through the steps of creating an optimized GC×GC method for your complex samples. Create a GC×GC method from scratch, or convert an existing 1D method to GC×GC. The tool will provide logical, step-by-step instructions to determine the secondary oven offset, second dimension column length, and experimentally evaluate stationary phases and peak capacity. Simply GC×GC takes a simple approach to GC×GC, helping you avoid unnecessary testing and streamline your method development cycle.

« back to product menu

L-PAL3

GC Autosampler

Available exclusively from LECO, our L-PAL3 autosampler offers increased vial capacity, discrimination-free GC injections (ultrafast injections), an automatic tool exchange to switch between injector types (liquid, headspace, or SPME), minimized carryover, and the sensing of vial bottoms to avoid mis-injections. All of these advantages come on a highly robust and integrated platform. The LECO L-PAL3 GC autosampler allows you to safely focus on identifying unknowns in your samples without experiencing downtime and uncertainty in your lab.

- Automation for up to 162 two mL samples, or 45 ten/twenty mL samples.

- Discrimination-free injection speeds with complete injection cycle time down to 100 milliseconds.

- Bottom-sensing technology ensures that even very small volumes can be sampled.

- Four separate models available so you may configure your package based on your autosampler needs.

L-PAL3 GC Autosampler for Liquid Injections

This CTC-based robot combines an autosampler and injector that operates in three dimensions of space, providing everything needed to perform standard liquid injections. This package includes a 5-position solvent wash station, tool for liquid syringe injections, mounting kit for 7890B GC, and a single tray holder with three trays (54-positions each) for 2 mL vials. This is a non-upgradable system.

L-PAL3 GC Autosampler for Liquid and Headspace Injections

This CTC-based robot combines an autosampler and injector that operates in three dimensions of space. It provides everything needed to perform standard liquid injections and static headspace injections. This package includes a heated agitator, 5-position solvent wash station, tool for liquid syringe injections, heated tool for headspace syringe, mounting kit for 7890B GC, and two tray holders; one with three trays (54-positions each) for two mL vials, and the second with three trays (15-positions each) for 10/20 mL vials. This configuration requires a manual exchange of tools between headspace and liquid injections.

ITEX Dynamic Headspace Tool

- Rapid and sensitive enrichment of volatile and semi-volatile compounds from solid, liquid and gaseous samples

- A choice of different adsorbents for best sensitivities

- No sample loops, transfer lines or valves, no contamination issues

- L-PAL3 Automatic Tool Exchange (ATX) enables head space, SPME, and ITEX-sampling within one sequence

L-PAL3 GC Autosampler For Liquid and SPME Injections

This CTC-based robot combines an autosampler and injector that operates in three dimensions of space. It provides everything needed to perform standard liquid injections and all SPME-type analyses (immersion, headspace). This package includes a heated agitator, 5-position solvent wash station, tools for liquid syringe and SPME fibers, SPME fiber conditioning station, mounting kit for 7890B GC, and two tray holders; one with three trays (54-positions each) for two ml vials, and the second with three trays (15-positions each) for 10/20 mL vials. This configuration requires a manual exchange of tools between SPME and liquid injections.

L-PAL3 GC AutoSampler for Liquid, Headspace, and SPME Injections

This CTC-based robot combines an autosampler and injector that operates in 3 dimensions of space. It provides everything needed to perform standard liquid, headspace, and SPME injections. This model allows for automatic switching of injection types, so method development can be automated. This package includes a heated agitator, 5-position solvent wash station, tools for headspace, liquid syringe and SPME fibers, and SPME fiber conditioning station, mounting kit for 7890B GC, and two tray holders; one with three trays (54-positions each) for two mL vials, and the second with three trays (15-positions each) for 10/20 mL vials.

L-PAL3 Details

- Models

-

L-PAL3 GC for Liquid Injections

-

L-PAL3 GC for Liquid and Headspace Injections

-

L-PAL3 GC for Liquid and SPME Injections

- L-PAL3 GC for Liquid, Headspace, and SPME Injections

-

- Options

- SPME Arrow

- ITEX Dynamic Headspace

L-PAL3 Autosampler