LECO

Empowering Results

LECO

Empowering Results

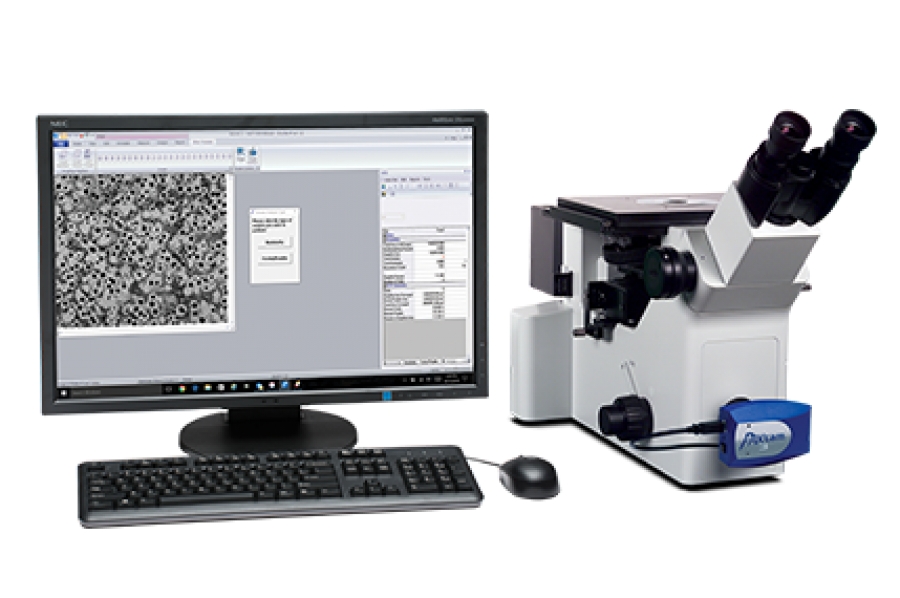

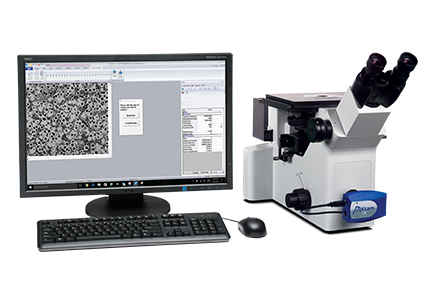

IA44

Image Analysis & Management System

Our IA44 Image Analysis/Management System easily transforms your raw data into valuable information that can effectively communicate your results. The combination of powerful image management capabilities and point-and-click simplicity provides a comprehensive solution for users with various levels of expertise. For added convenience, the PAX-it2™ software provides easy image management that saves, organizes, and retrieves all images and related data.

- Simple operation

- Powerful database search tool

- Customizable, application-specific toolbar buttons

- Comprehensive professional software tools

- Easy-to-use application wizards allow you to set up advanced applications from scratch or modify existing applications

- Sample data can be saved and organized within the system with a familiar file cabinet layout, or exported to Micosoft® Excel

IA44 Details

- Models

-

IA44

-

- Options

-

PAXcam™ Cameras

-

- Featured application

Porosity Analysis of Cast Aluminum - Product literature

IA44 - Consumables

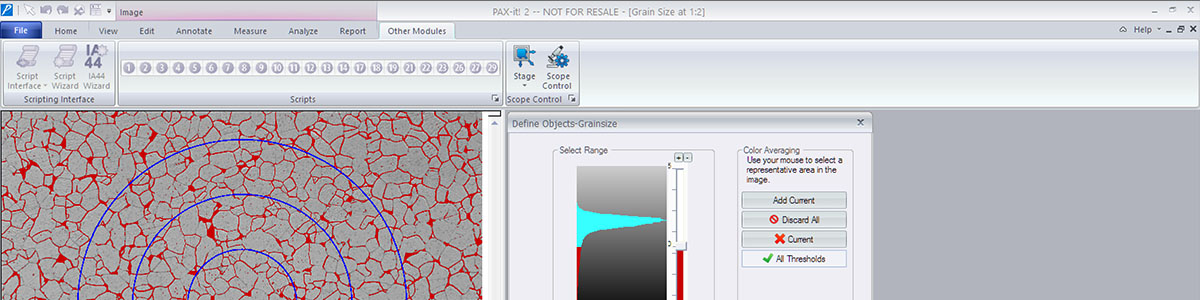

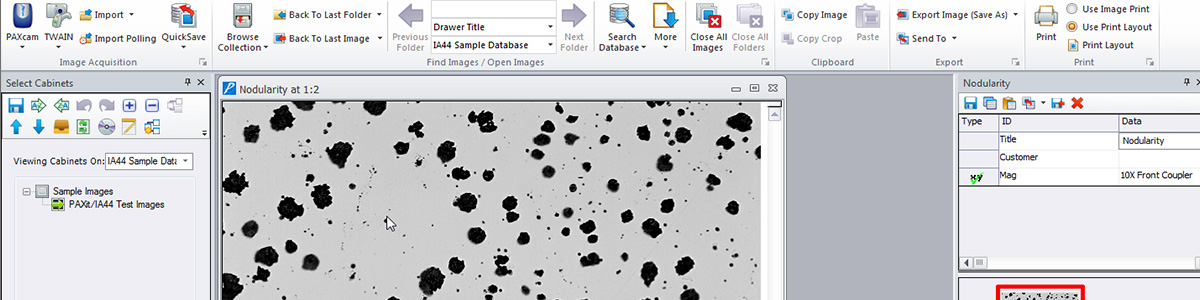

PAX-it™ 2 Image Management System

Imaging System for Science and Industry

PAX-it 2 allows you to easily capture, organize, analyze, network, transmit, and print high-resolution images. Through the use of a simple "electronic filing system," millions of images can be effectively organized and shared throughout your work environment, whether within the same building or around the world, streamlining your work process.

- Electronic filing system provides simple organizational structure

- Search, sort, and organize your images according to descriptive fields which fit your specific needs.

- Image processing functions, including image stitching, image fusion, and video/AVI file creation

- Measurement and analysis available, from simple linear and area measurements to complex image analysis

- Customizable report and presentation layouts for Microsoft Word®, Excel®, and PowerPoint®

- Various camera resolutions are available

- Modular software configurations

PAX-it Details

- Models

-

Standard measurement module

-

Core analysis module

- Grain size module

- Cast iron module

- Advanced measurement module

-

- Options

-

PAXcam Camera

-

- Product literature

PAX-it 2 - Consumables

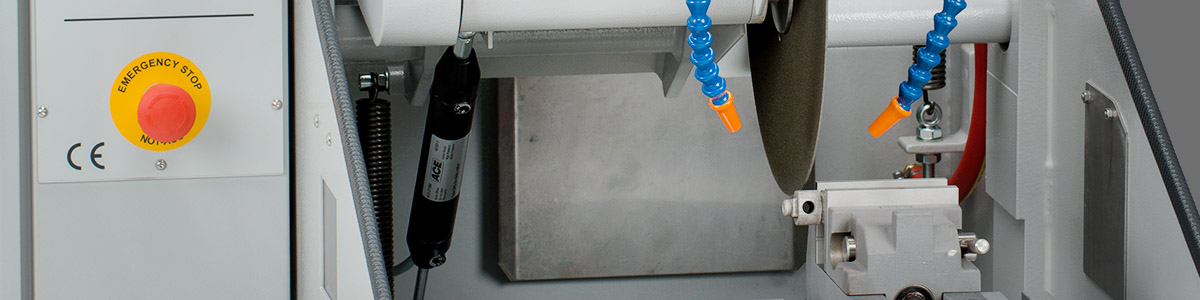

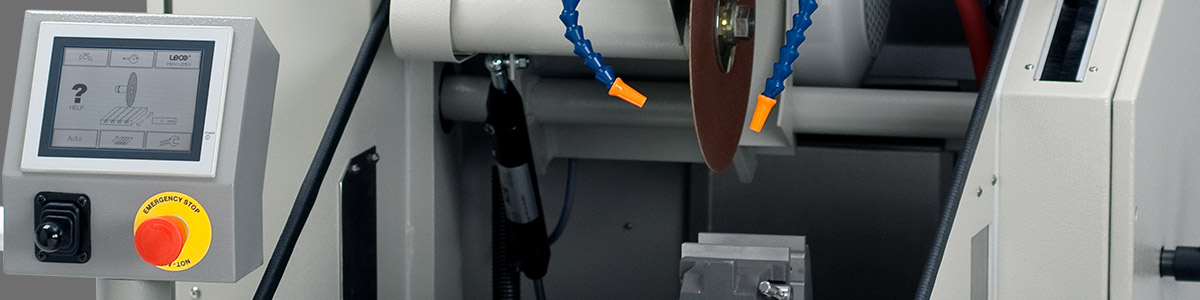

MSX255 Series

Benchtop Sectioning Machines

Ideal for creating medium-sized sections from automotive, ceramic, and composite materials. The MSX255 manual series sectioning machine offers 12 in (300 mm) blade capacity and a 5.4 HP (4 kW) motor.

- Simple manual operation with easy-to-operate control panel.

- Advanced spindle design offers long life and precise sectioning

- Welded steel construction for harsh production environments

- Large T-slotted table for flexible sample fixturing

- Channeled coolant drainage provides high flow rates and minimal debris build-up

- Cam-lock vise (right side) included

MSX255 Details

- Models

MSX255M- Manual with Fixed T-Slot Table

- 230V, 380V, or 460V

- Manual linear and radial feed with X- and Y-Table

- 230V, 380V, 460V

- Manual with Fixed T-Slot Table

- Options

- Filter bag system for convenient coolant system maintenance

- Integrated Y-table for parallel sectioning

- Product literature

MSX255 - Consumables

MSX250 Series

Sectioning Machines

The LECO MSX250 Series sectioning machine is ideal for obtaining medium-sized sections from automotive, ceramic, and composite materials. An automatic pulse sectioning feed rate with load control optimizes cutting time, with 10 in or 12 in (250 mm or 300 mm) blade capacity, and a 5.4 HP (4 kW) motor.

- Advanced spindle design offers long life and precise sectioning

- Convenient, easy-to-operate touch control panel capable of storing up to 10 applications

- Welded steel construction stands up to harsh production environments

- Large T-slotted table for fast and flexible sample fixturing

- Integrated Y-table for convenient parallel sectioning

- Isolated table design (X-axis) prevents contamination of linear slides

- Channeled coolant drainage provides high flow rates and minimizes debris build-up

MSX250 Details

- Models

MSX250A1 Series- Automatic Pulse Sectioning with Servo Control and Manual Y-Table

- 230V or 460V

- Automatic Pulse Sectioning with Servo Control and Manual Y-Table

- Options

- Filter bag system for convenient coolant system maintenance

- Support stand

- Variable Motor Speed

- Product literature

MSX250 - Consumables

MSX205 Series

Benchtop Sectioning Machines

The MSX205 Series sectioning machine is perfect for creating small sections for electronics and fasteners. This versatile sectioning machine offers both linear and radial feed configurations in a space-efficient benchtop model with 8 in (200 mm) blade capacity, 2.04 HP (1.5 kW) variable motor speed, and integrated 4.2 gallon (16 L) recirculating system.

- Advanced spindle design offers long life and precise sectioning

- Welded steel construction stands up to harsh production environments

- Large T-slotted table for fast and flexible sample fixturing

- Channeled coolant drainage provides high flow rates and minimizes debris build-up

- Integrated 4.2 gallon (16 L) recirculating system

- Optional integrated Y-table for convenient parallel sectioning

MSX205 Details

- Models

MSX205M Series- Manual with Fixed Y-Table

- 230V

- Dual with Moveable X- and Y-Table

- 230V

- Manual with Fixed Y-Table

- Options

- Integrated Y- and X-table for parallel sectioning

- Product literature

MSX205 - Consumables

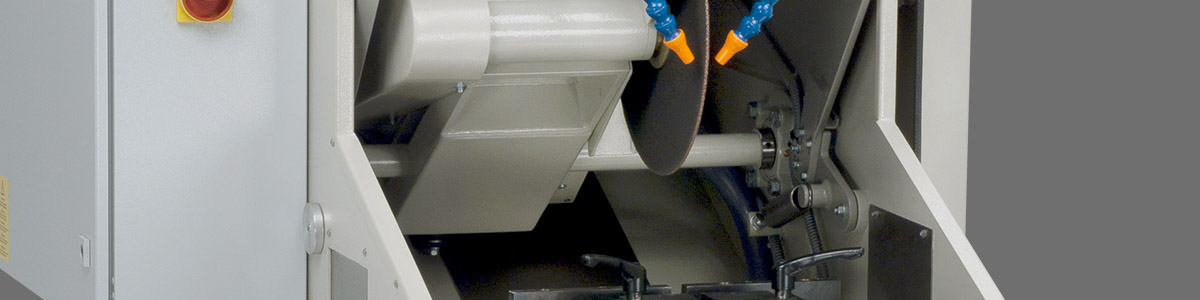

MSX305A Series

Sectioning Machines

The MSX305A Series is designed for sectioning large samples of many different types of materials using automated oscillation and servo-pulse sectioning. It is ideal for samples like induction-hardened parts, through-hardened tool steels, carburized pieces, and more. A manually adjustable Y-axis table provides easy sample position and parallel sectioning. Models support up to 14 in (350 mm) blades, and feature a powerful 10.05 HP (7.5 kW) motor and solid-steel construction.

- Production-grade spindle supports up to a 14 in (~350 mm) wheel with 1.25 in (32 mm) arbor

- Welded-steel construction for the production environment

- Optional catch basket for capturing small, sectioned samples

- 15.75 in (400 mm) x 15.75 in (400 mm) T-slotted table with large sectioning compartment for versatile sample fixturing

- 30 gallon (115 L) built-in coolant tank with coolant fluid level gauge

- Sealed electronic enclosure and removable side ports

- Convenient, easy-to-operate control panel

- Z-axis locking feature

- Handwheel-driven X- and Y-table for longitudinal section and sample position

MSX305A Details

- Models

MSX305A1 Series- Automatic, Pulse Servo Sectioning, with X- and Y-table

- 460V or 380-400V

- Automatic, Z-Axis, Oscillation and Pulse Servo Sectioning

- 460V or 380-400

- Automatic, Pulse Servo Sectioning, with X- and Y-table

- Options

- Catch Basket

- Laser Pointer

- Filter Fleece Blanket

- Product literature

MSX305A - Consumables

MSX432 Series

Sectioning Machines

The MSX432 Series is designed for sectioning large samples of high-alloy and hardened materials. Short contact times per stroke coupled with intense cooling provide the cold-cutting effects required for microstructural examination. Features 17 in (431.8 mm) blade capacity and a 20.1 HP motor.

- Advanced spindle design offers long life and precise sectioning

- Welded steel construction for the production environment

- Large T-slotted table for flexible sample fixturing

- Channeled coolant drainage provides high flow rates and minimal debris build-up

- Integrated Y-table for convenient parallel sectioning

- Isolated table design prevents contamination of linear slides

- 39 gallon (150 L) recirculating system

MSX432 Details

- Models

MSX432A1- Automatic with Y-table

-460V

- Automatic with Y-table

- Options

- Catch basket

- Brush port kit

- Filter sheet system

- Product literature

MSX432 - Consumables

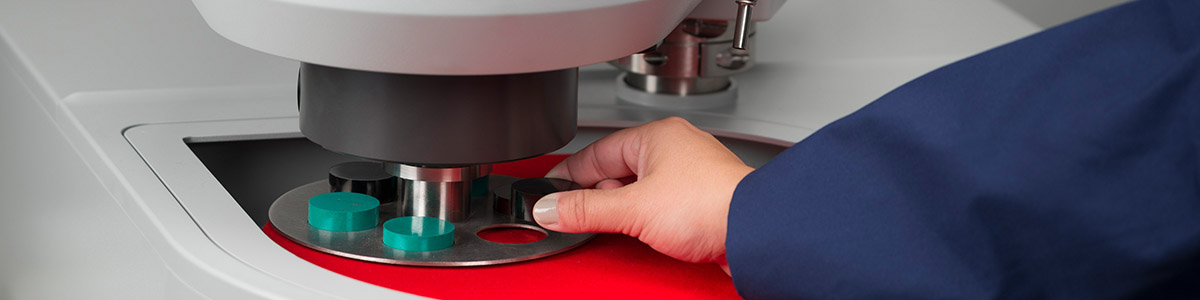

PX400 / PX500 Series

Advanced Grinder / Polisher

The PX400/PX500 grinder/polisher emphasizes ease-of-use while delivering exceptionally flat specimens to keep your metallography lab running smoothly. Designed with the latest technology, the PX400/PX500 provides an efficient, safe, reliable, and clean grinding/polishing solution through a number of innovative, user-friendly features.

Patent pending

- An intuitive touch-screen software with a variety of useful tools to simplify your grinding/polishing process.

- A spiral bowl design with automatic bowl wash system prevents drain clogs

- Slow indexing of the wheel after the cycle run for easy mount removal

- Individual sample feature provides slow rotation of the holder for easy mount loading

- More than 30 proven methods are built-in, and more can be created or downloaded

- Models offering both fixed and individual sample methods

- Up to five programmable metered fluid dispensers deliver consistent suspensions and extenders to meet every polishing objective

PX400/PX500 Details

- Models

-

PX400A Automatic Model

- Wheel Sizes: 8 in, 10 in, 200 mm, and 250 mm

- 115V or 230V

-

PX400S Standard Model

- Wheel Sizes: 8 in, 10 in, 200 mm, and 250 mm

- 115V or 230V

-

PX500A Automatic Model

- Wheel Sizes: 10 in, 12 in, 250 mm, and 300 mm

- 230V

-

- Options

-

Multiple dispenser configurations

-

- Product literature

PX400/PX500 - Consumables

PX300 Series

Manual Grinder / Polisher

Our PX300 Grinder/Polisher Series emphasizes ease-of-use while delivering specimens that are ideal for microhardness or microstructural work. Our PX300 provides an efficient, safe, reliable, and clean grinding/polishing solution for lower-volume laboratories.

Patent pending

- A spiral bowl design with automatic bowl wash system prevents drain clogs

- Emergency Stop Button quickly halts grinding operation

- Rugged structural and electronic components are made to withstand the toughest environments

- Adding the optional non-motorized head (at time of purchase or at a later date), adds these additional benefits:

- Run multiple samples at one time

- Improved consistency from operator-to-operator and run-to-run

PX300 Details

- Models

-

PX300 Base Models

- 115V or 230V

-

PX300 with Non-Motorized Head

- 115V or 230V

-

- Wheels

-

8 in, 10 in, 12 in, 200 mm, 250 mm, and 300 mm

-

- Product literature

PX300 - Consumables

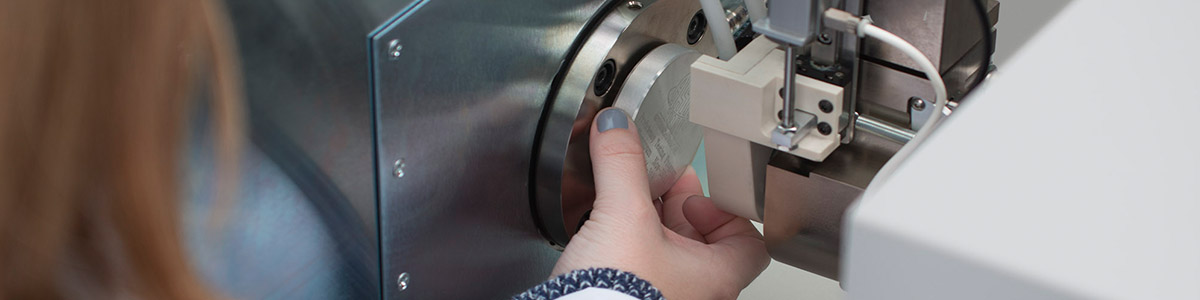

GDS900 Glow Discharge Spectrometer

Glow Discharge Atomic Emission Spectrometer

Our GDS900 Glow Discharge Spectrometer (GDS) offers you state-of-the-art technology designed specifically for your routine elemental determination in most conductive solid matrices. User-friendly Cornerstone® brand software is brought to the platform for increased usability, simplified reporting, and streamlined analysis times—saving you time in your lab.

Features

The glow discharge source brings a number of advantages including:

- Simple, linear calibrations when compared to other sources

- Controlled excitation that occurs away from the sample surface

- Reduced reference material consumption

- Automatic cleaning between samples saves time, minimizes matrix effects for increased precision

The detection system ensures stability, flexibility, and performance, with the following specifications:

- Full wavelength coverage from 160 nm to 460 nm

- 50 pm (0.050 nm) resolution to differentiate even the most complex features of bulk spectra

Optional CDP Analysis Support is available.

- Compositional depth profiling of solid electrically conductive samples

- Ideal for plating, galvanizing, cladding, and other conductive surface teatments

Applications

The GDS900 is ideal for bulk elemental determination in metals or other solid materials, like steel, cast iron, titanium, and other metals. When equipped with the CDP option, it expands the capability to include compositional depth profiling of surfaces like galvanizing, plating, heat treatments, and cladding.

Theory of Operation

Glow Discharge Spectrometry (GDS) is an analytical method for direct determination of the elemental composition of solid samples. A prepared flat sample is mounted on the glow discharge source, the source is evacuated and backfilled with argon. A constant electric field is applied between the sample (cathode) and the electrically grounded body of the lamp (anode).

These conditions result in the spontaneous formation of a stable, self–sustained discharge, which is called a glow discharge. The applied current is regulated by the power supply and the lamp voltage is held constant through regulation of the argon pressure.

As soon as the plasma is initiated, inert gas ions formed in the plasma are accelerated by the electric field toward the cathode. Through a process called cathodic sputtering, kinetic energy is transferred from the inert gas ions to the atoms on the sample surface, which causes some of these surface atoms to be ejected into the plasma.

Once the atoms are ejected into the plasma, they are subject to inelastic collisions with energetic electrons or metastable argon atoms. Energy transferred by such collisions causes the sputtered atoms to become electrically excited. The excited atoms quickly relax to a lower energy state by emitting photons.

The wavelength of each photon is determined by the electronic configuration of the atom from which it was emitted. Since each element has a unique electronic configuration, every element can be identified by its unique spectrochemical signature or emission spectrum.

A spectrometer is used to measure the emission signals from the glow discharge. To ensure that the media within the spectrometer is transparent to ultra-violet and visible light (160-460 nm), the entire optical system is purged with argon. Photosensitive Charge-Coupled Device (CCD) arrays are positioned at the focal plane in such a manner that the complete emission spectrum is recorded from 160 to 460 nm.

The CCD arrays convert the spectrum into an electrical signal, which is digitized and processed to remove dark current signal, normalize the pixel response, extend the dynamic range, and eliminate pixelation. Since the number of photons emitted by each element is proportional to its relative concentration in the sample, analyte concentrations can be deduced by calibration with reference samples of known composition.

GDS900 Details

Models

GDS900DCBO

- DC lamp for electrically conductive samples

- Bulk Elemental Analysis

- Rotary Vane Pump

GDS900DCEXBO

- DC lamp for electrically conductive samples

- Bulk Elemental Analysis with Extended Wavelength Range

- Rotary Vane Pump

GDS900DCQO

- DC lamp for electrically conductive samples

- Bulk Elemental and CDP Analysis

- Rotary Vane Pump

GDS900DCQEXO

- DC lamp for electrically conductive samples

- Bulk Elemental and CDP Analysis with Extended Wavelength Range

- Rotary Vane Pump

Optional Accessories

- Integrated Desk or Mobile Workstation

- High purity Gas Regulators

- Vacuum pump sound abatement enclosure

Featured application

Low Alloy SteelsProduct literature

Glow Discharge SpectroscopyConsumables